Top-Quality Foam Pads: Ultimate Guide to Shockproof, Soundproof & Custom Solutions

Jul 04,2025

Foam pads are lightweight, durable solutions used across industries for shock absorption, noise reduction, and sealing. Discover their top uses, materials, and custom options.

Top-Quality Foam Pads: Ultimate Guide to Shockproof, Soundproof & Custom Solutions

Introduction to Foam Pads

Foam pads are essential materials engineered to offer protective, shock-absorbing, and sound-dampening functions across multiple industries. Whether you're shipping fragile electronics or insulating a room, foam pads deliver unmatched cushioning performance. Their lightweight, porous design makes them a go-to solution for packaging, electronics, automotive interiors, and home furnishings.

These pads are typically manufactured from flexible polymers like PE, EVA, or PU, and can be custom-cut to meet diverse industrial needs. They're not just practical—they’re cost-effective, sustainable, and easy to install.

Core Features of Foam Pads

Shock Absorption

Foam pads exhibit excellent shock resistance due to their elastic cell structure. This makes them ideal for packaging fragile electronics, lab instruments, and glassware. When pressure is applied, the foam compresses to absorb the impact and instantly returns to its original form, preventing damage.

Noise Reduction

Thanks to their closed-cell or open-cell configurations, foam pads act as sound insulators. In machinery or entertainment systems, foam pads dampen operational noise, creating quieter environments. This makes them perfect for studios, home theaters, and industrial equipment.

Weather & Temperature Resistance

Many foam pad variants are built to withstand harsh conditions, ranging from -40℃ to 100℃. Whether it’s indoor climate control or outdoor protection, the material retains its performance without degradation. This durability is essential for automotive applications and outdoor installations.

Easy Customization

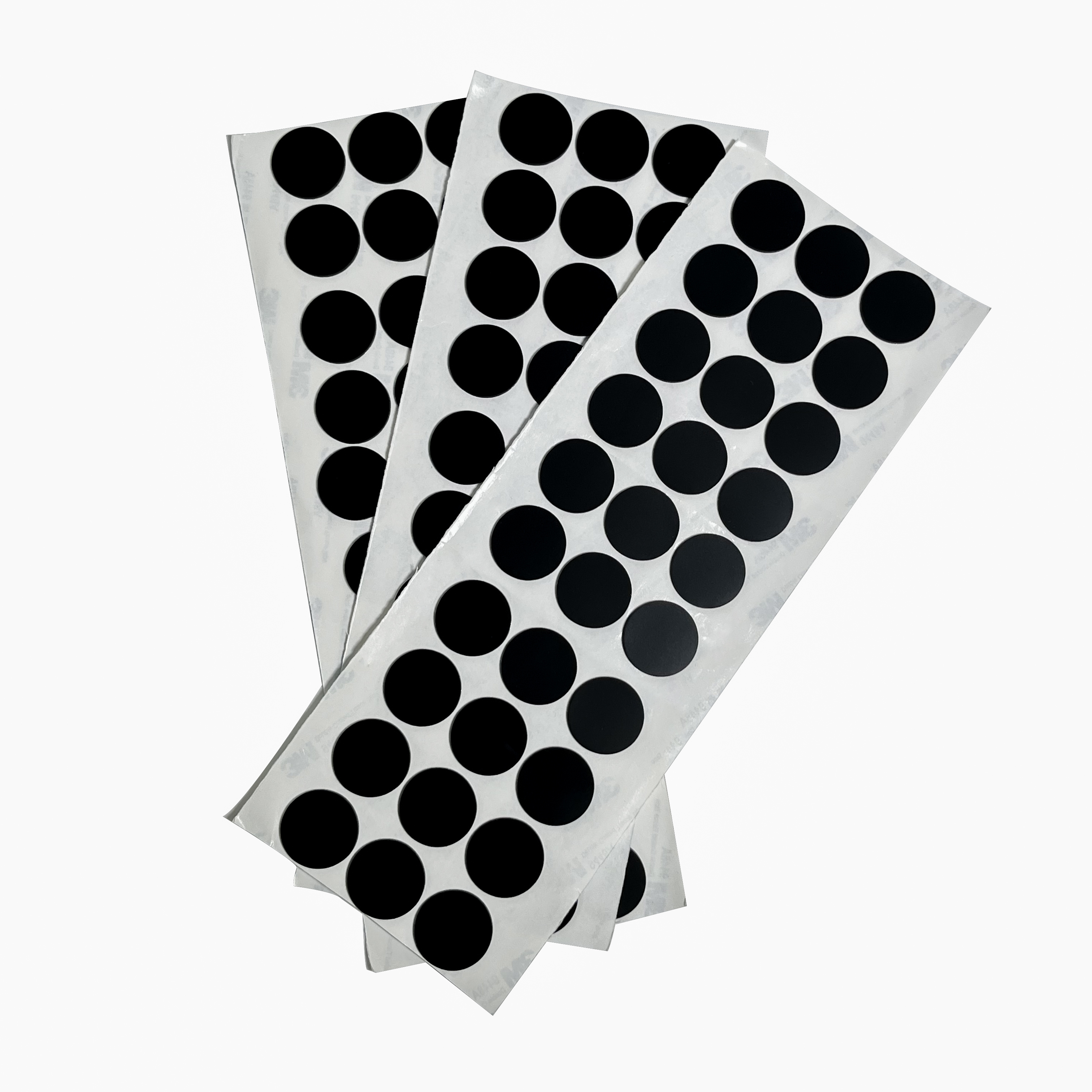

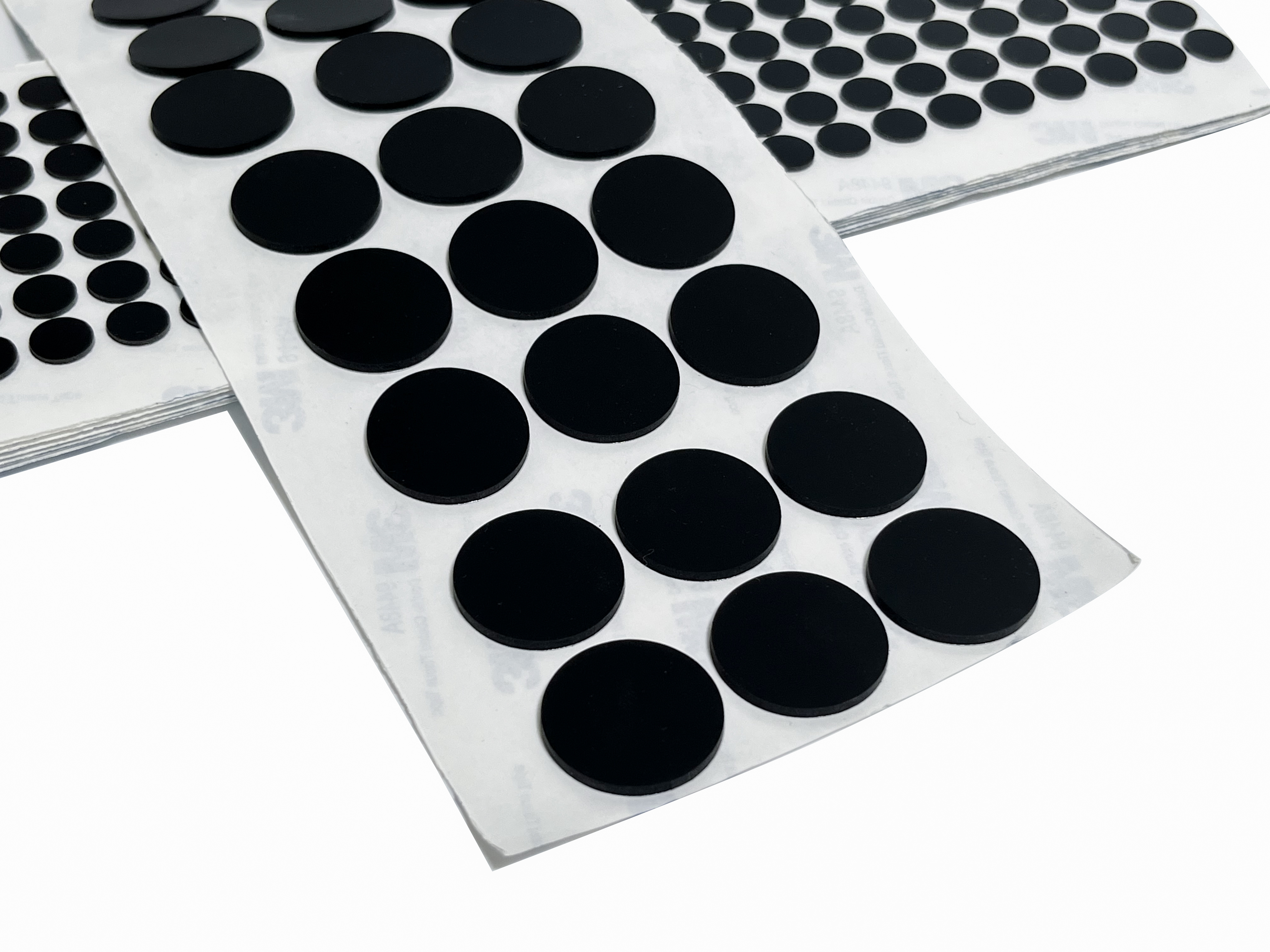

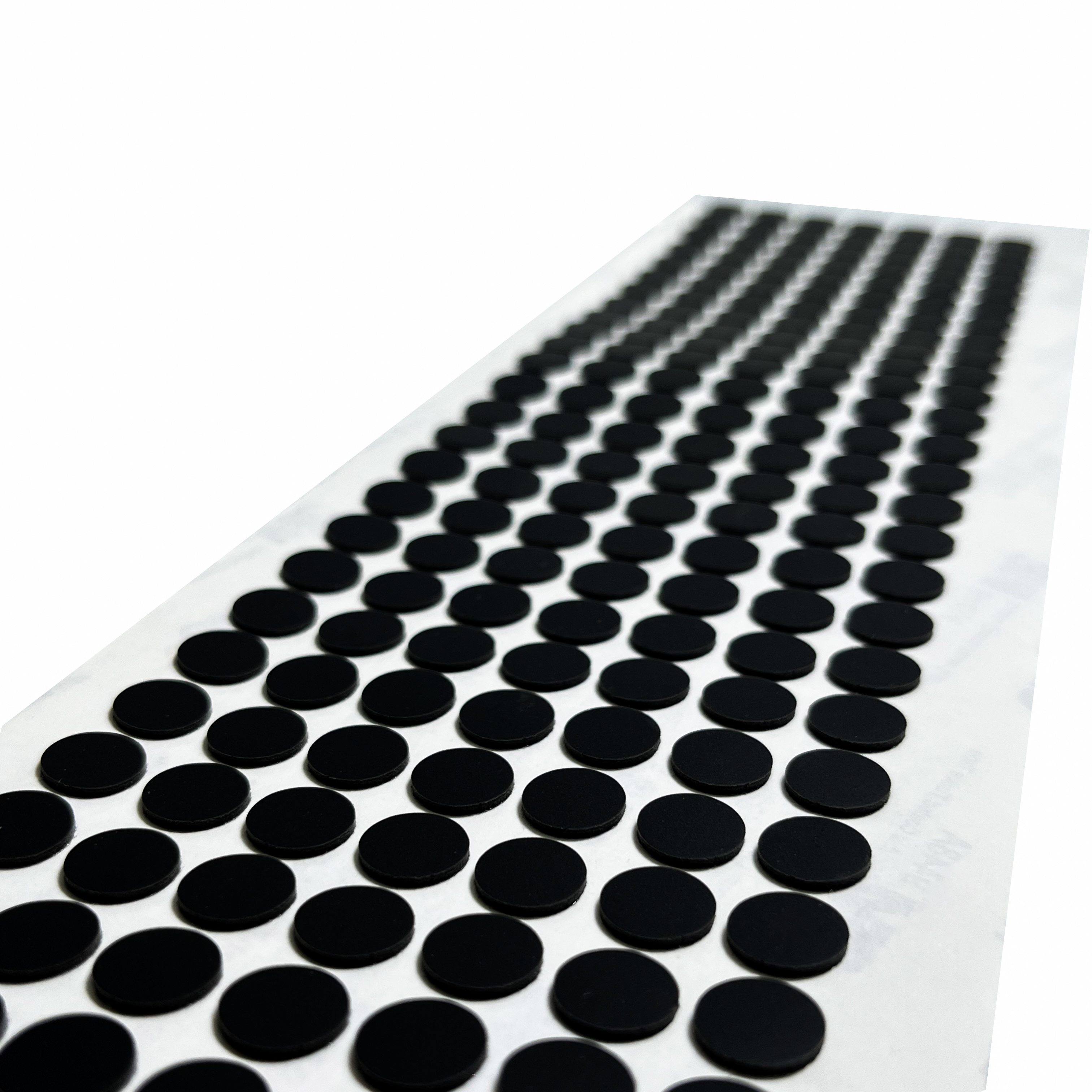

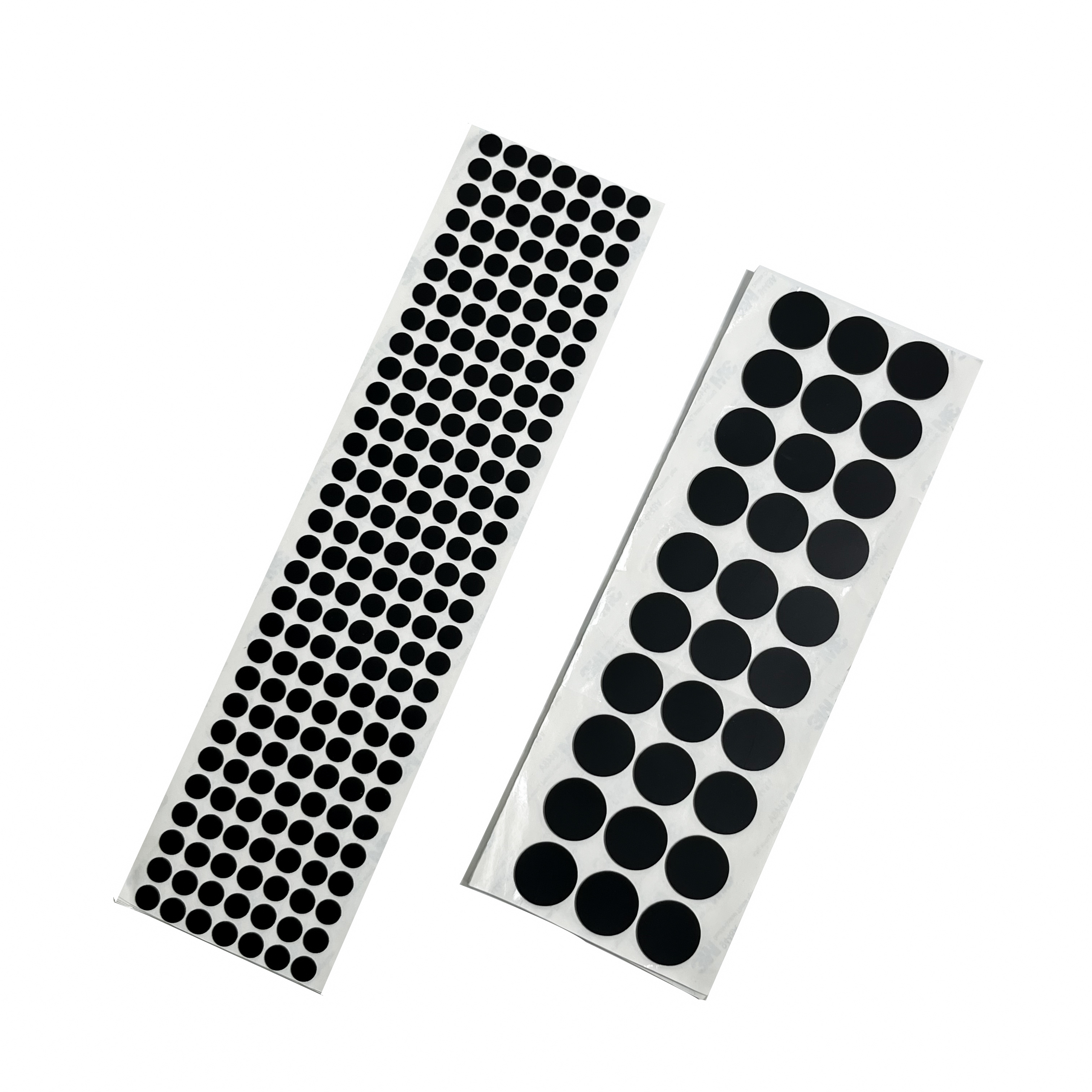

Foam pads can be easily tailored by cutting, stamping, or applying single/double-sided adhesive backing. They can be shaped into sheets, rolls, discs, or complex contours, providing engineers and designers with flexible options for every project.

Popular Foam Pad Materials

PE Foam Pads

Polyethylene (PE) foam is soft, waterproof, and resistant to moisture and chemicals. It's ideal for protective packaging in the electronics industry. Its low cost and adaptability make it a popular choice for general use.

EVA Foam Pads

Ethylene-Vinyl Acetate (EVA) foam is denser and more durable. It offers higher compression resistance, making it perfect for sports gear, yoga mats, and shoe insoles. EVA foam also provides moderate sound insulation and shock absorption.

PU Foam Pads

Polyurethane (PU) foam is known for its breathability and rebound quality. Commonly used in seat cushions, mattresses, and automotive interiors, PU foam provides ergonomic comfort with a soft, plush feel.

Industries That Rely on Foam Pads

Electronics Industry

Devices like smartphones, tablets, and gaming consoles are vulnerable to vibration and static damage. Foam pads act as anti-vibration buffers, shielding components during assembly or transport.

Packaging & Logistics

Foam inserts line boxes and crates to protect delicate instruments, glass products, and high-value items. They're essential in minimizing breakage during shipping.

Home & Furniture Applications

From anti-slip chair pads to soundproof underlayment for flooring, foam pads improve comfort and noise control at home.

Automotive Sector

Used under dashboards or seats, foam pads reduce road noise and enhance cabin comfort. In electric vehicles, they also aid in battery insulation and sealing.

Customization Capabilities

Foam pads offer near-limitless customization. Manufacturers can adjust:

Thickness & Density: For varying levels of cushioning

Color Options: To match branding or product aesthetics

Adhesive Types: Including heat-resistant or waterproof adhesives

Die-Cutting: Precision cuts to meet specific device or product contours

This level of flexibility ensures foam pads can fit virtually any application with ease.

Comparing Foam Types by Application

Choosing the right foam pad depends heavily on your specific application. Here's a quick comparison:

| Foam Type | Best Use | Key Benefit |

|---|---|---|

| PE Foam | Electronics packaging, tool inserts | Lightweight, waterproof, low cost |

| EVA Foam | Sports gear, footwear, yoga mats | Durable, impact-resistant |

| PU Foam | Furniture cushions, auto interiors | Breathable, soft, ergonomic |

This chart simplifies the selection process, ensuring you choose the best foam for your project’s requirements.

Environmental & Safety Considerations

Foam pads are not only practical but increasingly eco-conscious. Modern foam materials:

Are non-toxic and safe for direct contact.

Can be made from recycled materials.

Offer low VOC emissions, ideal for indoor use.

Choosing eco-friendly foam pads helps align with green manufacturing standards and customer expectations.

Innovations in Foam Pad Technology

The foam industry is evolving rapidly:

Smart Foam Pads: Integrated with sensors for pressure mapping in wearables or beds.

Bio-based Foams: Made from plant-derived materials like soy or castor oil.

Fire-retardant Formulations: Ideal for aerospace or automotive interiors.

These advancements push foam usage into high-tech and sustainable domains.

Installation Tips & Best Practices

For optimal performance:

Cut Cleanly: Use precision tools or CNC cutters.

Match Adhesive Type: Choose between permanent, removable, or double-sided adhesives based on use.

Avoid UV Exposure: Store in a cool, dry place to prevent material degradation.

Use Templates: For mass installation, use die-cut templates for accuracy and speed.

These steps ensure longevity and effectiveness of the foam padding.

Foam Pad Use Case Scenarios

Here are real-world applications showcasing the versatility of foam pads:

Electronics Packaging: Customized cutouts cradle devices in place during transit.

Flooring Underlay: Reduces sound transmission and adds thermal insulation.

Car Door Padding: Decreases vibration and enhances cabin quietness.

Wall Acoustic Panels: Used in studios and offices for noise control.

How to Choose the Right Foam Pad

Before making a purchase, consider:

Application Environment: Indoor vs outdoor, hot vs cold.

Compression Rate: How much pressure the pad will endure.

Water Resistance: Needed for humid or marine environments.

Adhesion: Whether you need temporary or permanent attachment.

Avoid common buyer mistakes like overestimating foam thickness or choosing the wrong adhesive type.

OEM & ODM Foam Pad Services

Many manufacturers offer full OEM/ODM services including:

Private Labeling

Customized Colors, Shapes, and Densities

Industry-Specific Designs

This allows businesses to develop foam solutions tailored to their brand and industry needs.

Bulk Purchasing & Wholesale Info

When buying foam pads in bulk:

MOQ (Minimum Order Quantity) may vary by material.

Lead Times typically range from 7–30 days depending on customization.

Global Shipping: Most factories ship via sea freight or express courier globally.

Bulk deals often come with tiered pricing, reducing the per-unit cost significantly.

Certifications & Quality Standards

For export and compliance, check if your supplier offers:

ISO 9001: Quality Management

ROHS: Restriction of Hazardous Substances

SGS Testing: Verified durability and chemical safety

These credentials ensure your foam pads meet international standards.

FAQs About Foam Pads

1. What is the best foam for soundproofing?

EVA and PU foams are best due to their density and structure, which trap and dampen sound effectively.

2. Can foam pads be reused?

Yes, high-quality foam pads like PE or EVA can be reused multiple times, especially in packaging and shipping.

3. Are foam pads waterproof?

PE and EVA foams offer excellent water resistance, making them suitable for outdoor or marine use.

4. Do you offer foam pad customization services?

Yes, most manufacturers offer complete customization including shape, size, thickness, color, and adhesive options.

5. Are these foam pads safe for skin contact?

Absolutely. Most foam pads are non-toxic and dermatologically safe, suitable for consumer and medical applications.

6. How long does foam padding last?

With proper storage and usage, foam pads can last from 5 to 10 years depending on the material type.

Conclusion

Foam pads are more than just simple cushioning products. They play a vital role in protecting, insulating, and customizing a wide range of products—from fragile electronics to stylish furniture. With numerous material options like PE, EVA, and PU, and extensive customization capabilities, foam pads are an essential component in modern manufacturing and everyday use.

Whether you're sourcing for industrial applications or personal DIY projects, understanding foam pad features, materials, and best use cases will help you make informed decisions that ensure safety, performance, and longevity.

PREVIOUS:

Contact Us

E-mail :

Phone/Wechat:

Add.:

Room 301, Building 1, No. 1 Hehe Street, Juzhou, Shijie Town, Dongguan City, Guangdong Province, China